Imagine walking through your local supermarket and scanning the shelves for your favorite spray deodorants, whipped cream, or hair products. Most of these items share a common technology: aerosol packaging. But what you may not realize is that the design and materials used to deliver these products are evolving fast, bringing an exciting blend of cost savings and quality improvements. Let’s explore how balancing cost and quality with flexible aerosol packaging is transforming the manufacturing and retail landscape.

What Makes Aerosol Packaging Flexible?

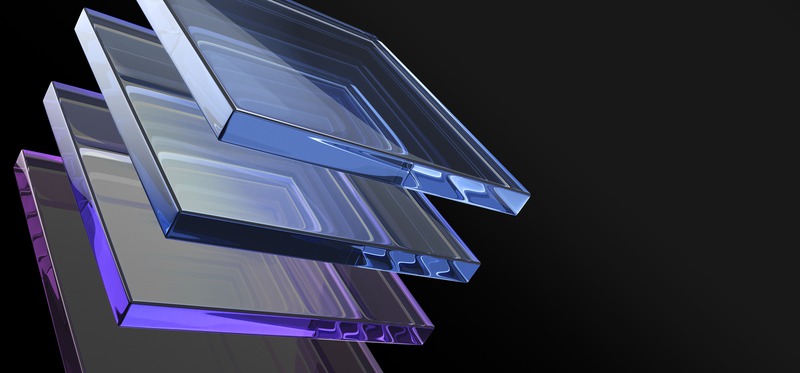

For decades, traditional aerosol cans were made from rigid metal or glass. They worked well for delivering pressurized sprays or foams, but they lacked versatility and came with significant manufacturing and shipping costs. Enter flexible aerosol packaging—a game-changing innovation. Unlike old-school rigid cans, flexible packaging uses multilayered films or pouches, often with a bag-on-valve or collapse-on-use design. This advancement makes packaging lighter, more adaptable, and often easier to recycle.

Key Advantages of Flexible Aerosol Packaging

-

Reduced Shipping Costs: Flexible packages weigh less, which means lower shipping and handling costs.

-

Storage Efficiency: These packages compress more easily, saving space in warehouses, trucks, and even store shelves.

-

Customization: Flexible materials can be molded into various shapes and sizes, allowing brands to tailor their products better to consumer needs.

-

Eco-Friendly Options: Many flexible packaging solutions are recyclable or use fewer raw materials than rigid cans.

How Cost Factors Come Into Play

While it’s tempting to focus on quality alone, cost is a major driver for manufacturers and brands. Flexible aerosol packaging offers several pathways to save money:

-

Lower raw material costs, thanks to lighter, thinner linings.

-

Reduced carbon footprint, as less energy is needed throughout the packaging lifecycle.

-

Smaller initial investments are needed to create unique or limited-edition product runs since flexible designs require less complex molds.

-

Fewer losses from damaged, dented, or corroded packaging compared to metal cans.

But, of course, companies must ask: can these cost savings happen without sacrificing the quality their customers expect?

The Importance of Quality in Aerosol Packaging

Consumers care about more than just the price tag—they’re looking for products that perform well and feel safe. Aerosol packaging must:

-

Keep contents stable and airtight until use.

-

Dispense product smoothly, whether in sprays or foams.

-

Remain durable during transport, storage, and handling.

-

Meet all relevant health, safety, and regulatory standards.

To maintain quality, manufacturers turn to advanced films and sealing technologies. Many flexible aerosol packages now outperform their rigid predecessors in terms of shelf life and product purity.

Design Flexibility Creates Branding Opportunities

The versatility of flexible aerosol packaging opens a world of design possibilities. Instead of being limited by the shape or surface of a traditional can, brands can create custom forms, graphics, and tactile finishes. This flexibility boosts shelf appeal and allows for seasonal or themed designs without extensive retooling.

How Flexible Packaging Enables Creative Branding

-

Unique shapes catch the eye and provide ergonomic benefits to users.

-

360-degree printing lets brands share more information or creative designs.

-

Textures (like soft-touch or gloss) enhance premiumization and perceived value.

Sustainability and the Shift Toward Eco-Friendly Solutions

As consumers become more environmentally conscious, brands are under increasing pressure to go green. Flexible aerosol packaging can be a step in the right direction, using less plastic and fewer resources in production. However, recyclability depends on local facilities and the materials chosen during design. The best packaging solutions take a holistic approach, considering not just cost and quality but also the product’s end-of-life impact.

Tips for More Sustainable Aerosol Packaging

-

Choose packaging films that are widely recyclable or compostable.

-

Minimize extra components (caps, collars) to reduce complexity.

-

Educate customers on how to dispose of empty packaging responsibly.

-

Partner with suppliers who prioritize renewable energy and materials.

Striking the Right Cost-Quality Balance

So, how do brands maintain the sweet spot—delivering high quality without breaking the bank? Here are a few proven approaches:

-

Invest in R&D: Prototyping and rigorous testing ensure new packaging meets performance standards.

-

Listen to Customers: Surveys and feedback help identify pain points so improvements can be made efficiently.

-

Collaborate with Supply Chain Partners: Working closely with packaging experts can reveal creative ways to save costs without sacrificing quality.

-

Monitor Market Trends: Staying ahead of consumer demand and regulatory shifts reduces costly redesigns later.

For example, a personal care brand might switch from a rigid can to a flexible pouch that delivers a consistent spray for truly innovative products such as foaming pomade. The flexible design means users get every last drop, while the lighter weight helps keep prices reasonable, all without compromising product performance.

Applications That Benefit from Flexible Aerosol Packaging

Flexible aerosol technology isn’t just limited to one market. Many industries have found ways to boost value by innovating their packaging:

-

Personal Care: Hair sprays, shaving creams, sunscreens, and lotions.

-

Household: Cleaners, air fresheners, and pest control sprays.

-

Food: Whipped creams, cooking sprays, and flavorings.

-

Medical: Topical sprays, wound care, and inhalers.

Imagine a customer grabbing a hairspray finishing spray in a flexible package that fits perfectly in her purse, never leaks and dispenses smoothly every time. That’s the type of user-friendly advancement flexible packaging can enable.

Challenges Facing Flexible Aerosol Packaging

For all its benefits, flexible aerosol packaging is not without hurdles. Here’s what brands must keep in mind:

-

Barrier Properties: Some products are sensitive to air or light, so packaging must have the right protective layers.

-

Consumer Perceptions: Some shoppers may associate “flexible” with “flimsy” unless messages emphasize strength and quality.

-

Filling and Dispensing Technology: New machinery and processes are sometimes needed, requiring investment and training.

-

Regulatory Compliance: Each region may have its own rules about pressurized containers and safe packaging disposal.

Navigating these challenges requires agility—another area where flexible packaging can shine if the right solutions are adopted early on.

Consumer Experience and the Future of Flexible Aerosols

The journey doesn’t end once a product lands on the shelf. The real test is how well it functions in customers’ hands and fits into their everyday lives. Unique features like no-mess dispensing, easy squeezing, and portability drive loyalty and repeat sales. As more brands embrace this technology, we can expect ongoing improvements and a race to deliver the best combination of cost savings and premium quality.

Plus, the customization and comfort provided by flexible aerosol packaging are key reasons why categories such as hairspray light-medium hold are seeing increased consumer satisfaction. The ability to control the amount dispensed and the precise application appeals to both professionals and casual users.

Final Thoughts

Ultimately, the switch to flexible aerosol packaging is about balancing the needs of everyone in the supply chain: manufacturers, brands, retailers, and customers alike. When companies listen to feedback, embrace innovation, and keep an eye on both cost and quality, they set themselves up for success in a fast-evolving marketplace. Flexible packaging may not be the answer for every product, but it’s certainly earning a place on more and more shelves—and in the hands of satisfied shoppers around the world.